ROMBO Chains are the favored choice among OEMs in USA, Europe, Middle East, Latin America and Southeast Asia.

Discover our

unique characteristics

Exceptional tensile

The incorporation of Hardened High Tensile Pins in chains that are designed according to the American Heavy Series standards enhances their working load capacity and provides improved fatigue resistance in applications with high loads and fluctuating conditions.

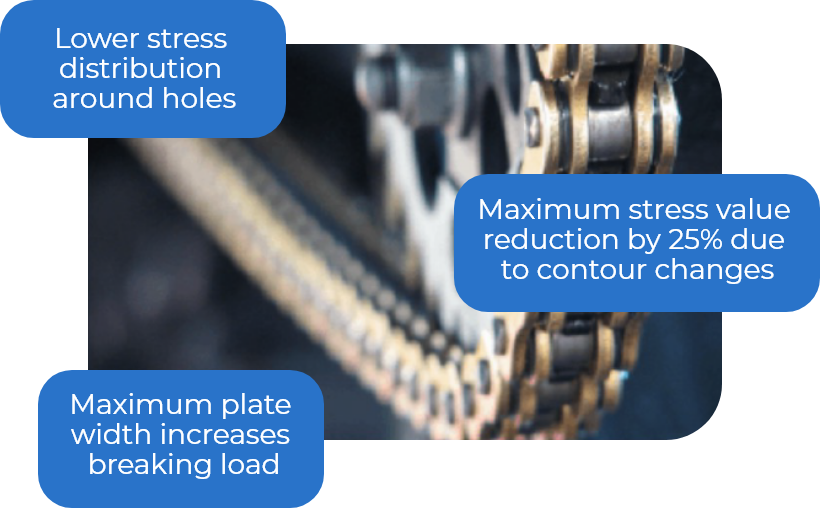

The use of high precision tools in Superior Plate Manufacturing guarantees a larger contact area and enhances fatigue resistance.

Shot Piercing and Pre-stressing processes are utilized to increase dynamic strength and fatigue life. The plates and rollers undergo shot peening with round metallic shots to induce compressive stress, resulting in heightened fatigue resistance and improved appearance.

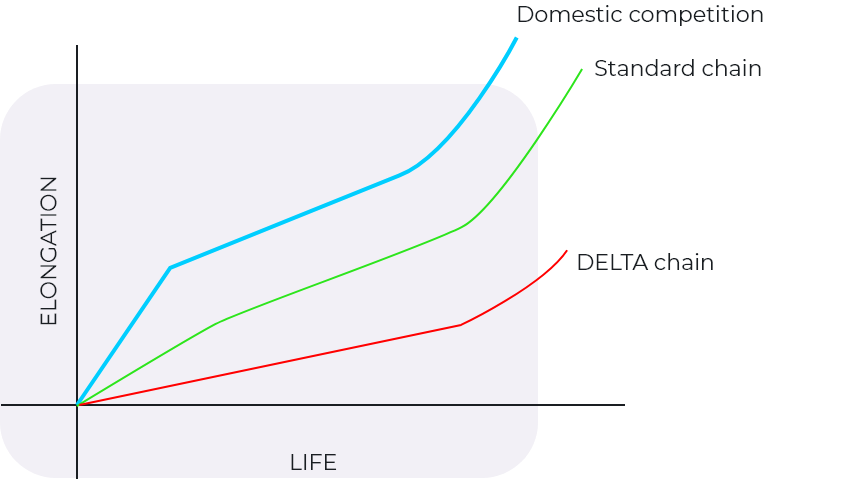

HIGH ENDURANCE

A significant increase of over 15% has been observed in breaking load and fatigue strength when compared to international standards.

The use of high precision tools in Superior Plate Manufacturing guarantees a larger contact area and enhances fatigue resistance.

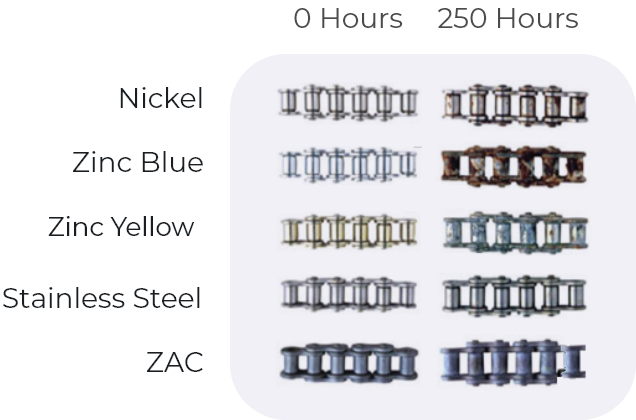

Rombo Chains also offer excellent corrosion resistance as they are coated with TIDC’s ZAC, an anti-corrosion coating. These chains have been designed to withstand a minimum of 250 hours of salt spray testing, following ASTM B 117 guidelines

EFFICIENT POWER TRANSMISSION

The advantage of operating with fewer rollers compared to standard roller chains of the same pitch is provided by the uniquely designed double-pitch chains of Rombo. This feature reduces the overall weight of the chain while still maintaining its mechanical strength, resulting in efficiency for power transmission applications.

Rombo chains have exceptional load-carrying capabilities, allowing for the transmission of high levels of mechanical power.

The use of rollers in the chain ensures smooth contact with sprockets and reduces frictional losses, enabling efficient power transfer even over long distances.

Rombo’s adaptability to different power transmission requirements makes it the preferred choice for various industries and industrial applications, including material handling, construction, agriculture, aerospace, automotive, heavy machinery, and manufacturing.

LONG-TERM DURABILITY

Superior materials such as high-grade stainless steel are renowned for their exceptional resistance to corrosion, tarnish, and wear, thereby significantly prolonging the lifespan of chains.

Rombo chains are meticulously crafted using advanced precision tools and processes, resulting in the creation of robust and meticulously constructed chains that are capable of enduring daily wear and tear.

Thorough quality checks are conducted at every stage of production to ensure precise dimensions, impeccable smoothness, and unwavering reliability of each individual link.

Every link undergoes meticulous shaping to optimize both strength and flexibility. This deliberate structuring effectively eliminates weak points, reduces the risk of breakage, and ensures the chain maintains its integrity throughout its entire lifespan.

MAINTENANCE FREE

Rombo Chains are also widely used for applications where maintenance is complex like food processing, printing, pharmaceuticals and electronics.

Made with unique power alloy bushes Rombo chains are impregnated with special oil, enabling maintenance free wear life up to two times in excess of standard chains.

COMPLIANT WITH INTERNATIONAL SPECIFICATIONS OF BRITISH AND AMERICAN STANDARDS

Rombo ensures that their products meet the requirements of American industries by complying with American National Standards Institute (ANSI) standards. This ensures compatibility across various applications.

Rombo consistently produces chains that fulfill ANSI standards by using high-quality materials, precision engineering, and rigorous quality control processes.

Adherence to British Standards Institution (BSI) ensures seamless integration of Rombo chains with the requirements of British industries, facilitating smooth operations and optimal performance.

Rombo’s compliance with both ANSI and BSI standards ensures that their chains are compatible with the equipment and machinery used in American and British industries, minimizing the need for costly modifications or replacements.

Meeting both American and British standards results in increased safety levels, reducing the risk of workplace accidents and injuries.

MODULAR DESIGN, STRUCTURAL INTEGRITY AND SCALABILITY

The integration of diamonds and rhombuses in an innovative construction technique results in a flexible and aesthetically appealing pattern.- The pattern can be easily rearranged, interlocked, and extended, allowing for highly flexible and adaptable structures.

The modular design offers countless possibilities in terms of size, shape, and overall arrangement.- The unique geometry of the rhombus in Rombo chains, with equal length sides and congruent opposite angles, along with interconnected diamonds, helps to evenly distribute forces and enhance structural integrity.

The modularity of Rombo chains allows for easy scalability, with effortless extension and compression.- Rombo chains can also be easily dismantled and reconfigured, making them ideal for dynamic industrial applications.

RELIABILITY, TRACEABILITY AND CONSISTENCY

We place great importance on ensuring reliability in every step of our processes, beginning with obtaining raw materials from reputable and authorized sources.

Our completed products can be traced back to different stages of production, starting from the sourcing of materials. Maintaining detailed records of both quality and raw materials is of utmost importance and is done for a minimum of five years.

Our production systems adhere to strict batch-to-batch product compliance in order to maintain consistency and meet all specifications.

QUALITY PROCESS

INCOMING

RAW MATERIAL

MANUFACTURING

ASSEMBLY

AUDIT PACKAGING

QUALITY

SIGN-OFF

CUSTOMIZABLE SOLUTIONS FOR DIVERSE INDUSTRIAL APPLICATIONS

CONSTRUCTION

AGRICULTURE

MINING

FERTILIZER

STEEL

SUGAR

AUTOMOBILE

ESCALATOR

GENERAL ENGINEERING

Automated Storage and Retrieval Systems (ASRS)

Cement

Packaging

heavy Engineering

COMPLETE CHAIN

COMPANY

COMPLETE CHAIN COMPANY

WITH OVER CUSTOMIZABLE 25000 SKUS,

ROMBO OFFERS A WIDE-SUITE OF INDUSTRIAL CHAIN PRODUCTS

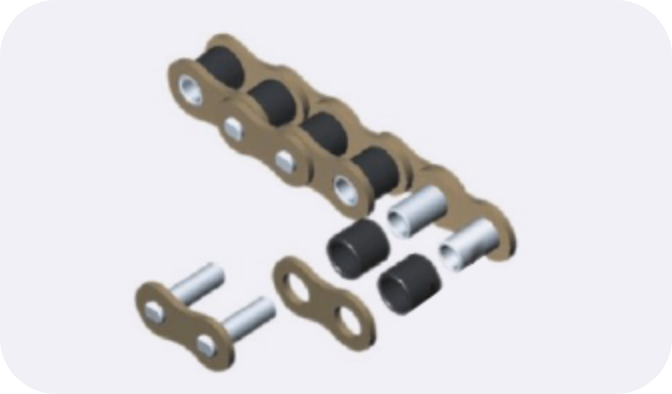

STANDARD ROLLER CHAINS

ADAPTED CHAINS

AGRICULTURAL CHAINS

LEAF CHAINS

CONVEYOR CHAINS

SPECIALITY PRODUCTS

OUR EDGE

Customer-focused innovation-driven R&D

Product quality and safety assurance aligned with international standards

Commitment to rigorous testing and certification

Excellent service reliability and on-time delivery

Distribution warehouses in Europe and the USA